Laser micro welding is used for welding very small components through the use of laser light. The light is used to rapidly melt and fuse the target metals together. This is an important process because it creates a precise and strong bond between the parts. The medical, electronic and automotive industries frequently use this process for joining their small components together.

Micro welding is a cost-effective process that can often save time and money in comparison to Metal Laser Sintering or other methods of machining a complex part in its entirety. Making individual parts or micro-sized components that are easy to machine and control and then welding them into a final assembly is often the best solution from a quality, time and cost savings perspective.

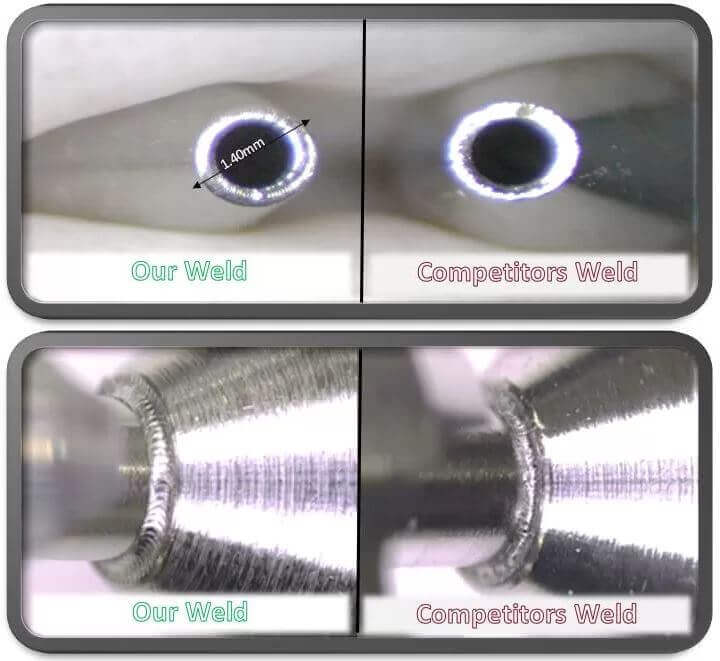

Below we have provided comparison photos of a micro-welded medical part where the customer was unhappy with the quality and lead time of their previous supplier. We were able to provide them a much stronger weld that had a smoother finish. We were also able to complete a large order for them in less than half of the time that their previous supplier was projecting.

LASER DYNAMICS, INC.

Laser processing is a basic need for most companies. Whether you’re searching for identifying your product with permanent logos, mass-producing identical parts through precise laser cutting, or hermetically welding two workpieces together, the upfront price of the lasers and training is costly to both finances and time. Laser Dynamics provides the expertise, fast turn-around time, and top-of-the-line lasers to ensure that your product not only functions as intended but looks great!