BARCODE CAPABILITIES

CODE TYPES AND IN-HOUSE VERIFICATION

BARCODE CAPABILITIES

Laser Dynamics offers a variety of 2D barcode laser marking. We currently have the ability to laser mark 22 code types in our software, including Data Matrix codes, UPC codes, Dot Codes, PDF codes, EAN codes, QR codes, and, of course, standard barcodes. With a barcode scanner, we can read each coded part that we mark. Each part can then be logged into a file and loaded into a software program for later analysis and quality control measures. These files can be made available at the customer’s request.

Below is an extensive list of all the 2D barcodes we have laser marked in the past for our customers. Please contact us if you have any questions about our 2D barcode laser marking services.

INTERLEAVED 2 of 5 BARCODE

Also known as ITF, I-2/5, Code 25 Interleaved, I 2 of 5, I/L 2 of 5, 2 of 5, 2/5 Interleaved, ANSI/AIM ITF-5, ANSI/AIM I-25, Uniform Symbology Spec ITF, USS ITF 2/5

CHARACTER SET: [0-9]

STANDARD 2 of 5 BARCODE

Also known as Code 25 (Industrial), Industrial 2 of 5, IATA 2 of 5, Code 2 of 5

CHARACTER SET: [0-9]

CODE 11 BARCODE

Also known as USD-8

CHARACTER SET: [0-9] [-]

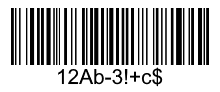

CODE 39 BARCODE

Also known as Code 3-of-9, Code 3/9, LOGMARS, USD-3, Type 39, USS Code 39, MIL-STD-1189B, MIL-STD-129, MIL-STD-2073-1C, MIL-STD-129N, HIBC LIC

CHARACTER SET: [0-9] [A-Z] [% + $ / . -]

CODE 93 BARCODE

Also known as USS-93, USS Code 93

CHARACTER SET: [0-9] [A-Z] [% + $ / . -]

UPC A BARCODE

Also known as UCC-12, UPC 12

CHARACTER SET: 12 digits [0-9]

UPC E BARCODE

Also known as Universal Product Code

CHARACTER SET: 7 digits [0-9]

CODABAR BARCODE

Also known as 2 of 7 Code, Code 27, Ames Code, Monarch, NW-7, USD-4, Codabar, ANSI/AIM BC3-1995

CHARACTER SET: [0-9] [A-D] [- $ : / . +]

CODE 128 A BARCODE

Also known as Canada Post, USPS, ISBT 128,

USS Code 128, ISS Code 128

CHARACTER SET: [0-9] [A-Z] [Symbols]

CODE 128 B BARCODE

Also known as Canada Post, USPS, ISBT 128

USS Code 128, ISS Code 128

CHARACTER SET: [0-9] [A-Z] [a-z] [Symbols]

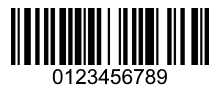

CODE 128 C BARCODE

Also known as UCC 128, EAN 128, SSCC-18, SCC-14, GTIN (EAN14)

CHARACTER SET: [0-9]

EAN-8 BARCODE

Also known as ISBN, ISSN, Bookland, EAN/JAN-8

CHARACTER SET: 8 digits [0-9]

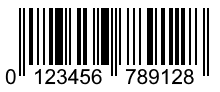

EAN-13 BARCODE

Also known as ISBN, ISSN, Bookland, EAN/JAN-13, EAN13

CHARACTER SET: 13 digits [0-9]

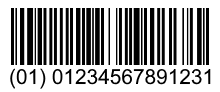

EAN-14 BARCODE

Also known as DUN-14, SCC-14, UPC Shipping Container Code-14, Global Trade Item Number-14, GTIN-14, European Article Number-14, EAN-14, GS1-14

CHARACTER SET: 14 digits [0-9]

DATA MATRIX BARCODE

Also known as GSA Data Matrix

CHARACTER SET: [All ASCII Characters]

DOT CODE BARCODE

There are no other well known names for this barcode

CHARACTER SET: [All ASCII Characters]

PDF 417 CODE BARCODE

There are no other well known names for this barcode

CHARACTER SET: [All ASCII Characters]

QR CODE BARCODE

There are no other well known names for this barcode

CHARACTER SET: [0-9] [A-Z] [$ % * + – . / :]

BARCODE VERIFIERS VS. BARCODE READERS

Barcode scanners, also known as barcode readers, are devices used to capture and read coded information. When scanned with a barcode reader, a barcode is translated into a series of numbers and letters. The scanned data is then sent to an internal software program that deciphers the data.

Similar to barcode readers, barcode verifiers capture an image of the barcode. However, that is where the similarities between the two devices end. The barcode verifier sends the captured data to its internal software where it is analyzed and where the barcode format is verified. Format examples are GS1, HIBCC and MIL-STD-130. The verifier also grades the contrast of each individual cell in the code, as well as performing dozens of other checks to the code such as shape and uniformity.

Verifying the 2D barcode laser marking on a product allows manufacturers to take corrective action before proceeding with an entire production run. Barcode verifiers provide this data to the manufacturer through the means of printed verification reports which you can read more about here.

THE NEED FOR VERIFICATION

Verification can alert printing issues and nonconforming barcodes outside of the quality parameters early in production. Barcode verification ensures that products have been marked or engraved correctly. In addition to ensuring immediate conformance, a barcode verifier generates reports, certifying the quality of our laser marked barcodes.

• MEDICAL UDI RULE

In 2013, the FDA (Food and Drug Administration) established the UDI Rule to regulate medical devices sold in the United States. The UDI Rule is a unique device identification system for manufacturers and distributors selling medical devices for patient use. The FDA has mandated that, by the year 2020, all medical devices are to contain a Unique Device Identifier (UDI).

A Unique Device Identifier (UDI) is a barcode containing a product’s lot number, serial number, and expiration date, if appropriate. The FDA ruling requires that a graded barcode label (according to GS1 or HIBCC rules) must be on all applicable medical devices.

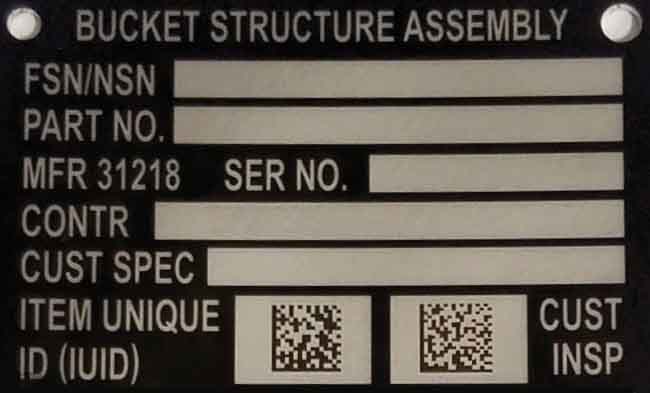

• MILITARY MIL-STD-130

According to MIL-STD-130, items made and sold to the United States Department of Defense must use a UID (Unique Identification) code. The purpose of this edict is to help the United States government maintain a record of purchasing details, maintenance logs, and outdated products in a centralized registry. The UID typically consists of a traditional barcode or a 2D Data Matrix, which is usually accompanied by human-readable text information.

GS1 SYSTEM OF STANDARDS

GS1 is the organization responsible for developing and maintaining various global standards for business commerce. The best known of these standards is the barcode standard. GS1 barcodes are common throughout the United States and scanned more than six billion times every day.

The GS1 standard’s key to success is the ability to create a common business language, which uniquely identifies, captures, and automatically shares vital information about products, locations, assets, and more. GS1 standards are an efficient method for traceability and part identification.

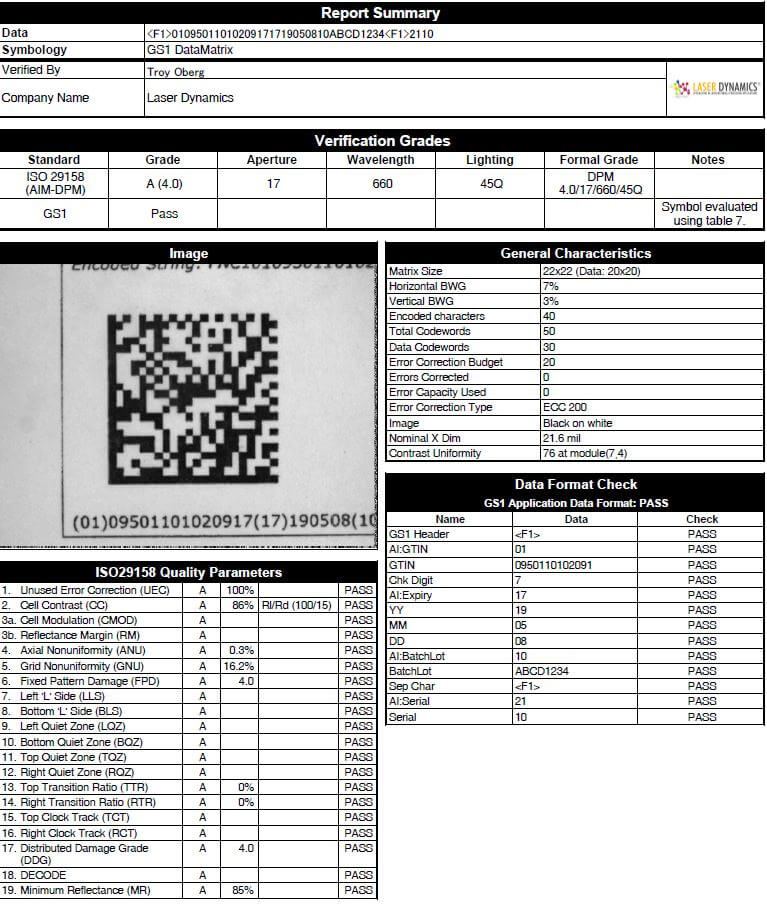

VERIFICATION REPORT EXAMPLE (GS1)

GS1 Data Matrix Reports provide a series of diagnostic information about the 2D Data Matrix symbols. The verification program is capable of finding any problem with the symbol’s conformance and provides a high level of confidence that the symbol works correctly. Furthermore, GS1 Data Matrix Reports are capable of verifying that the final product bearing the symbol meets the requirements of the GS1 standard in terms of encoded data, print quality, symbol shape, data format and more.

Laser Dynamics offers and provides GS1 Data Matrix Report Summaries for our customers requiring 2D barcode laser marking on their products. The reports will be sent with the parts after completion upon customer request.

Grade: is a numeric grade based on conformance to the ISO/IEC 15415 standard. The rankings are 0-4, (4 being the best and 0 being the worst). The report also has a grade based on ANSI verification, which is used on a scale of A-F (A being the best and F being the worst).

Aperture: is a number that reflects the hole diameter that is currently being used by the verifier to read the code. Each specific aperture setting lets in a fixed or calibrated amount of light into the system. Various standards may require a specific aperture to be used during verification. Some of these reference numbers can be found in the ISO/IEC 15416 standard.

Wavelength: the GS1 standard wavelength of the light to be used during verification is 660nm.

Lighting: verifiers have multiple lighting options to grade according to various grading methodologies and standards. When verifying using ISO 15415, only the 45Q lighting option is available for selection; when verifying using ISO 29158 all lighting options are available for selection

Formal Grade: is reported as a combination of the grade and verifier settings used. It should be shown in the format “Grade / Aperture / Wavelength / Lighting”.